In the ferromanganese chemical formula, which is considered one of the most important alloys in the industry, there are three main elements, manganese, iron, and carbon and there are other elements such as silicon, phosphorus, and sulfur at specific percentages. But usually, the chemical formula of ferromanganese alloy is as FeMn shows. Ferromanganese is usually used in two standard forms (high carbon) and low carbon in the industry, in which case the ferromanganese chemical formula is shown as HCFeMn and LCFeMn, respectively.

Since the properties and behavior of ferromanganese are determined by its constituent elements, it is very important to understand the chemical elements and their effects on the alloy’s properties. Therefore, we have dedicated this article to examining the ferromanganese chemical formula and its elemental composition.

Pars Manganese Naqsh Jahan with decades of experience in the field of producing ferroalloys has played a significant role in the industry. The commitment of this company is to provide the highest quality to both domestic and international customers. For consultation and ordering ferromanganese, you can contact us via email.

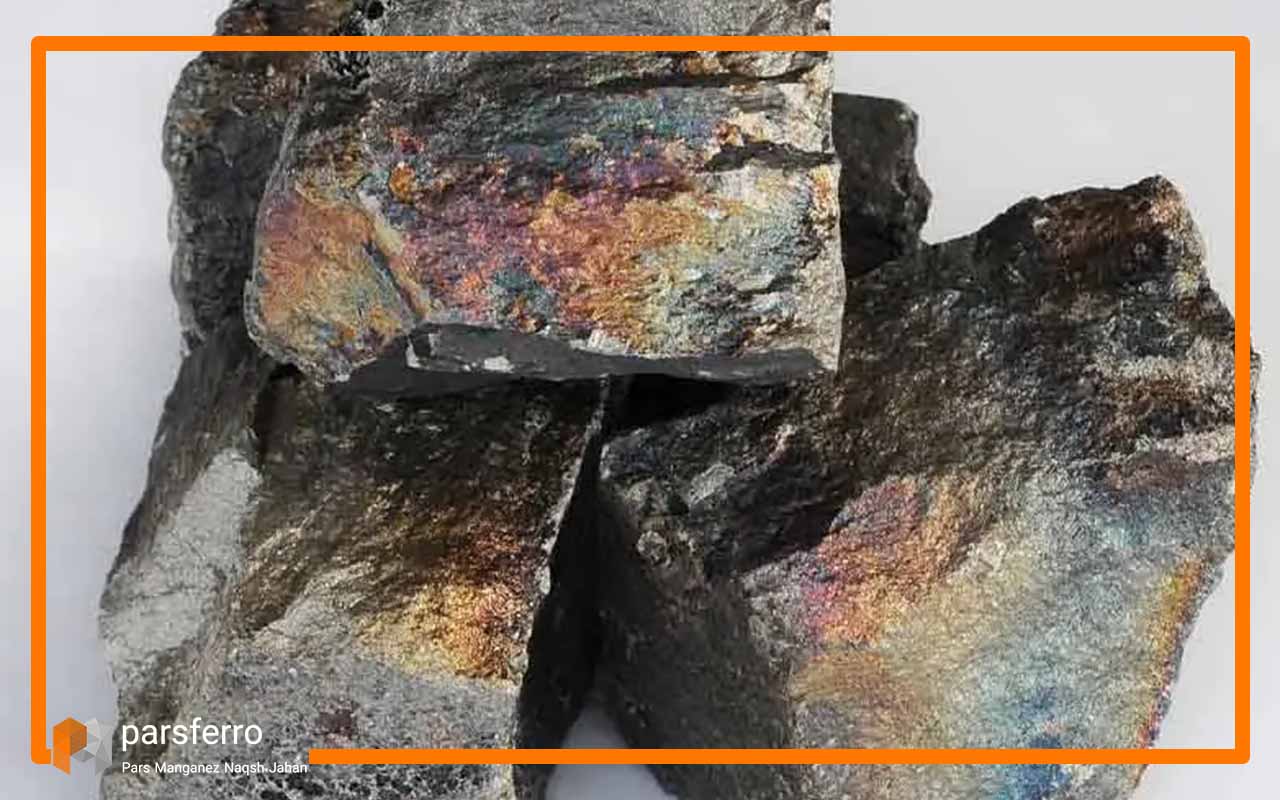

ferromanganese chemical formula indicates its elemental composition. In general, ferromanganese is an alloy composed primarily of iron (Fe) and manganese (Mn) with trace amounts of other elements. The general ferromanganese chemical formula is often represented as FeMn, indicating the coexistence of iron and manganese in the alloy. However, it’s important to note that the actual composition may vary based on the specific type and grade of ferromanganese.

Ferromanganese Alloy Types

Ferromanganese comes in different grades and types, each designed to meet specific industrial requirements. The two main types are high-carbon ferromanganese (HCFeMn) and low-carbon ferromanganese (LCFeMn).

read more: What is ferromanganese alloy?

high carbon ferromanganese

Chemical formula: HCFeMn

Composition: Typically contains about 70-80% manganese, 6-8% carbon, and residual iron with small amounts of other elements.

Application: It is widely used in steel production to introduce manganese and carbon into the steelmaking process.

low carbon ferromanganese

Chemical formula: LCFeMn

Composition: Contains lower carbon content, typically around 0.1% or less, making it suitable for applications where reduced carbon levels are critical.

Application: Used in the production of stainless steel and other alloys where lower carbon levels are required.

The following table summarizes the values of the elements in the ferromanganese chemical formula:

Table 1. The percentage of elements in the chemical formula of ferromanganese (high carbon and low carbon)

| Chemical formula | HCFeMn | LCFeMn |

| %Mn | 65%-79% | 80%-81% |

| C | 8.0% max | 0.1%-3.5% min |

| Si | 2.0% max | 105-35% min |

| P | 0.5% max | 0.05%-0.35% max |

| S | 0.03% | 0.03% max |

ferromanganese element’s role in the final properties of ally

Each of the elements used in the ferromanganese chemical formula plays specific roles in the properties of the ferromanganese alloy, which are briefly explained below:

read more: ferromanganese composition

Iron: As one of the main components of ferromanganese, iron helps to strengthen the mechanical properties of steel. This includes increasing strength, hardness, and wear resistance. The presence of iron in ferromanganese can affect the internal structure of steel and play a role in controlling the grain formation process in steel.

Manganese: As an important additive, Manganese gives extra strength to steel. This strength enhancement is due to manganese’s ability to increase hardness and resistance to stress and fatigue. Manganese plays an important role in controlling the strength of steel and its thermal stability. This feature is important in thermal processes such as thermo annealing and helps prevent the formation of undesirable compounds. Manganese increases the corrosion resistance of steel, which is very important in the production of stainless steel.

Carbon: In certain types of ferromanganese, such as high-carbon ferromanganese, carbon is present as an additional alloying element. Adding carbon to steel can increase its resistance to pressure and wear. Carbon plays an important role in the thermal properties of steel. Adding different amounts of carbon can have a great effect on the strength and hardness of steels at different temperatures.

Phosphorus: Phosphorus, as an alloying element, can lower the melting point of steel. This feature can be used in steel production processes such as welding. Phosphorus can play a role and influence the structure of steel grain as a composite element.

Sulfur: Sulfur can play a role in controlling steel rust as an alloying element. This element may help increase resistance to rust and cope with environmental influences.

Silicon: The presence of silicon can be effective in improving the electrical and magnetic properties of steel. This property can be considered in certain applications such as the production of transformers and electric motors. Silicon may reduce the unwanted effects of non-metallic materials and be effective in controlling pollutants in the steel production process.

3 important significance of ferromanganese in metallurgy

ferromanganese plays a crucial role in the metallurgical industry, particularly in steelmaking. The addition of ferromanganese to molten steel during the production process imparts desirable properties to the final product. Here are three key roles of ferromanganese in metallurgy:

- Oxidation and Desulfurization: Ferromanganese helps in the removal of oxygen and sulfur from molten steel, preventing the formation of undesirable oxides and sulfides that can compromise the quality of steel.

- Alloying element: Manganese, a key component of ferromanganese, acts as a strong alloying element. It increases the strength, hardness, and wear resistance of steel, making it suitable for various applications.

- Carbon control: In the case of high-carbon ferromanganese, the carbon content contributes to the steel’s hardness and strength. This is especially important in applications where these properties are critical, such as the production of certain types of structural steel.

conclusion

Ferromanganese, a key alloy in the metallurgical industry, is generally represented by the chemical formula FeMn, denoting its composition of iron (Fe) and manganese (Mn). It exists in high-carbon (HCFeMn) and low-carbon (LCFeMn) forms, with HCFeMn containing approximately 70-80% manganese, 6-8% carbon, and trace elements, while LCFeMn has lower carbon content. The alloy’s properties are influenced by its elemental composition, where iron strengthens steel, manganese enhances strength and corrosion resistance, carbon contributes to wear resistance, and other elements play specific roles. Ferromanganese’s crucial roles in metallurgy include oxidation and desulfurization, acting as an alloying element for improved steel properties, and controlling carbon content for applications requiring hardness and strength in steel production.

No comment