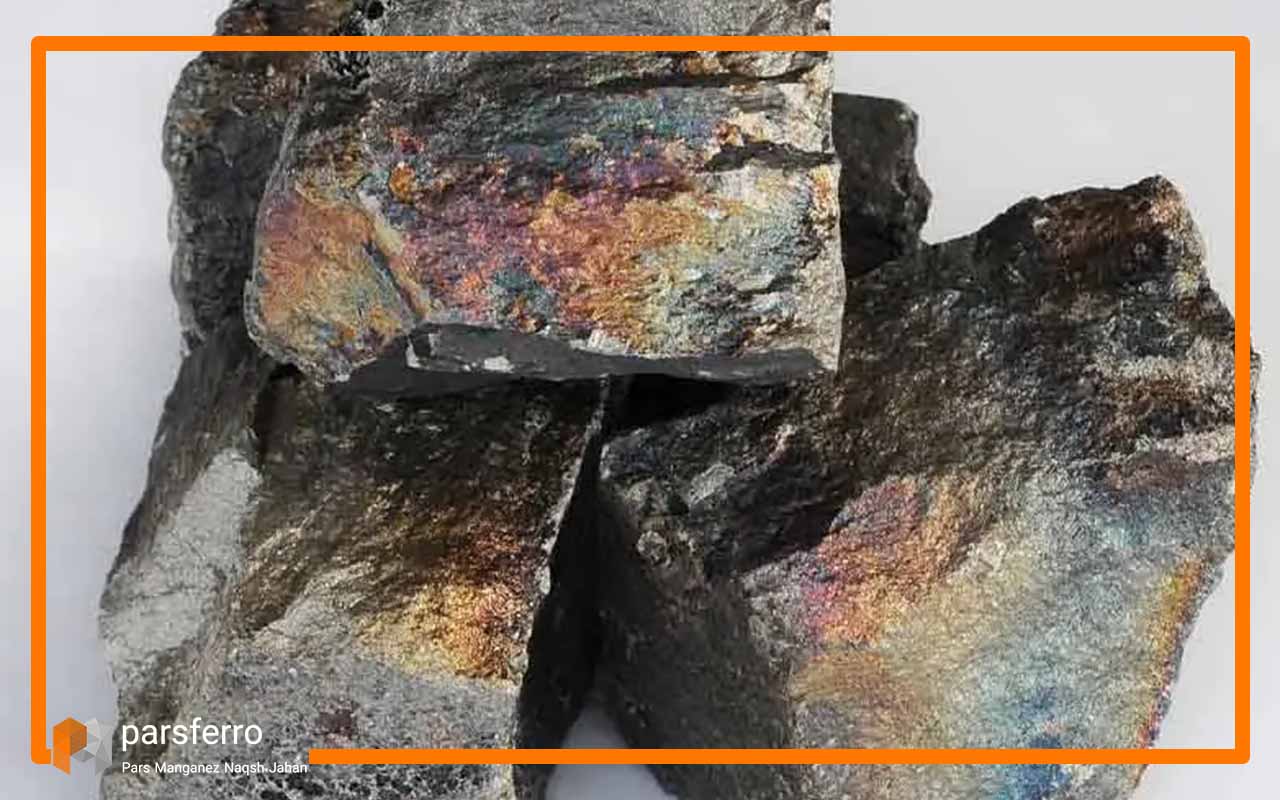

low carbon ferro manganese (LCFeMn) is an alloy composed primarily of manganese (Mn), iron (Fe), and carbon (C), and its carbon content is usually kept low to minimize the formation of unwanted carbides. ferromanganese is commonly used in the production of steel and stainless steel to introduce manganese and reduce the carbon content. In this article, we will review the composition, formula, properties, applications, and low carbon ferro manganese price.

read more: What is ferromanganese alloy?

To inquire about the low carbon ferro manganese price, how to order, or consultation, you can contact Pars Manganese Naqsh Jahan experts via email.

Low carbon ferro manganese composition & formula

Low carbon ferro manganese is an alloy composed primarily of manganese (Mn), iron (Fe), and carbon (C), with trace amounts of other elements. The standard composition typically includes around 70-80% manganese, 0.1-1.5% carbon, and the remaining portion consisting mainly of iron. Additionally, small amounts of silicon (Si), phosphorus (P), sulfur (S), and other elements may be present depending on the specific production process and requirements.

The formula for low carbon ferro manganese can be represented as LCFeMn, signifying its primary components of iron (Fe), manganese (Mn), and carbon (C).

read more: ferromanganese composition

LCFeMn vs HCFeMn

The primary distinction between LCFeMn and HCFeMn is in their carbon content, and consequently, their influence on the properties of the steel in which they are used. LCFeMn is preferred when lower carbon levels and enhanced malleability are desired, while HCFeMn is chosen for applications that require higher hardness and wear resistance. The selection between the two depends on the specific requirements of the steel and the intended application.

Low carbon ferro manganese properties

- Here are some key characteristics and properties of low carbon ferro manganese

- enhanced malleability and ductility: low carbon ferro manganese contributes to the improvement of steel’s malleability and ductility, making it easier to form and shape during manufacturing processes.

- deoxidizing agent: The alloy acts as a strong deoxidizing agent, helping to remove oxygen from molten steel, thereby reducing the risk of brittleness and improving the overall quality of the steel.

- increased hardenability: LCFeMn enhances the hardenability of steel, making it suitable for applications where hardness and strength are critical, such as in the production of construction materials and industrial equipment.

- corrosion resistance: The presence of manganese in the alloy contributes to the corrosion resistance of steel, making it more durable in various environments.

- reduced carbon content: As the name suggests, Low Carbon Ferro Manganese contains a relatively low carbon content, minimizing the risk of undesired carbide formation and ensuring the steel maintains desirable properties.

Application of high carbon ferro manganese

Following, we intend to introduce to you the most applications of low carbon ferro manganese:

Steel Production

The primary application of Low Carbon Ferro Manganese is in the production of steel. It is added to steelmaking processes to improve the mechanical and metallurgical properties of the final product.

Alloying Agent

LCFeMn serves as a crucial alloying agent, enhancing the performance of steel in terms of strength, toughness, and resistance to wear.

Deoxidizer in foundries

Foundries use Low Carbon Ferro Manganese as a deoxidizing agent in the production of cast iron, helping eliminate impurities and enhance the quality of the castings.

Railroad equipment

ferromanganese is employed in the manufacturing of railroad tracks and components due to its ability to improve the hardness and durability of steel.

low carbon ferro manganese price

The low carbon ferro manganese price is influenced by various factors, including the global steel demand, the cost of raw materials, energy prices, and market dynamics. Prices can fluctuate based on these factors, and consumers often negotiate contracts based on prevailing market conditions.

low carbon ferro manganese specification

The specification of low carbon ferro manganese outlines the key parameters and characteristics that define its composition and properties. While specific specifications may vary slightly depending on the producer and application, here is a general overview of typical specifications for LCFeMn:

Chemical Composition

- Manganese (Mn): 70-80%

- Carbon (C): 0.1-1.5%

- Silicon (Si): 1.5% max

- Phosphorus (P): 0.30% max

- Sulfur (S): 0.05% max

- Other Trace Elements: May include small amounts of other elements, such as chromium, nickel, and copper.

Physical Properties

- Density: Typically around 7.2 g/cm³.

- Melting Point: The melting point is influenced by the specific composition but generally ranges from 1100°C to 1300°C.

Particle Size

LCFeMn is often available in various particle sizes, ranging from granules to fine powder. The choice of particle size can depend on the specific requirements of the steelmaking or casting process.

Carbon Recovery

The efficiency of carbon recovery is an important factor, and specifications may include a target percentage of carbon recovery during the steelmaking process.

Packaging

LCFeMn is typically packaged in containers or bags, with weight specifications based on industry standards. Common packaging sizes include 25 kg bags or larger containers for bulk transportation.

It’s essential to note that these specifications provide a general guideline, and actual product specifications can vary between manufacturers and based on the intended use. Prospective buyers or users of LCFeMn should refer to the specific technical data sheets provided by the manufacturer for precise information regarding the product’s composition and properties. These technical documents offer detailed insights into the characteristics of the alloy and ensure that it meets the required standards for the intended application.

low carbon manganese price in Pars Manganese Naqhsh Jahan

Pars Manganese Naqhsh Jahan Company plays a significant role as a supplier of widely-used alloys for the domestic steel industry and exports these products to various parts of the world. Among these alloys, ferromanganese is a vital element in the steelmaking industry. The company takes pride in producing and exporting low-carbon and high-carbon ferromanganese with the best quality worldwide. For consultation and information on the low carbon ferro manganese price, you can contact us via email.

Conclusion

Low carbon ferro manganese plays a crucial role in the steel industry, contributing to the production of high-quality steel with enhanced properties. Its composition, properties, and uses make it an indispensable alloy in various applications. As industries continue to prioritize sustainability and low-carbon alternatives, the demand for alloys like Low Carbon Ferro Manganese is likely to persist and evolve, shaping the future of steel manufacturing.

Reviews

There are no reviews yet.