Silico manganese, a crucial alloy in the steelmaking industry, plays a pivotal role in enhancing the properties of steel and is used as an alloying element and deoxidizer. Comprising silicon, manganese, and iron, this alloy is renowned for its ability to improve the strength and durability of steel. As a result, silico manganese is in high demand globally, influencing its market price. One of the key factors that determine silico manganese price is the quality and grade of the alloy.

Silico manganese in steelmaking

Silico manganese is an alloy produced by the combination of silicon, manganese, and iron, typically in varying ratios. It is used as a deoxidizing and desulfurizing agent in the steelmaking process, contributing to the refinement of steel quality. The silicon content enhances the steel’s strength and hardness, while manganese improves its workability and resistance to wear and rupture. This alloy is integral to the production of high-quality steel in various industries, including construction, automotive, and infrastructure. The following table provides some important information about silico-manganese:

Table1. silico-manganese specification

| Melting point | 1150℃ |

| Main silico manganese usage | Deoxidizer in steelmaking |

| Packaging | 25 and 50 kg bags, 200 kg drum and 1ton bags |

| Particle size | 2-25, 10-50 and 10-80 mm |

read more: silico manganese uses

Quality and Grades of silico Manganese

The quality Manganeses of silico manganese refer to the composition and purity of the alloy. Different grades have varying silicon and manganese content, affecting their performance and application in steelmaking. Higher-quality silico manganese often commands a premium price due to its superior ability to impart desirable properties to steel.

- Silicon Content

Silicon is a key component of silico manganese and significantly influences its price. Higher silicon content generally results in improved strength and hardness of steel. As a result, alloys with elevated silicon levels are more sought after in applications where durability and toughness are critical.

- Manganese Content

The manganese content is another crucial factor affecting silico manganese prices. Manganese enhances the workability of steel, making it more malleable and ductile. Alloys with higher manganese content are preferred in industries that require steel with excellent formability.

- Impurities and Purity

The presence of impurities in silico manganese can diminish its effectiveness in steel production. High-purity silico manganese is often more expensive due to the additional processing required to remove impurities. The purity of the alloy is vital for achieving the desired steel quality.

Types of silico-manganese grades

Silico-manganese is divided into grades 1 and 2, and the difference between these two is mostly the percentage of manganese, silicon and phosphorus impurity, which differentiates the purity and properties of these two grades. The following table shows the chemical composition of these two silico-manganese grades.

Table2. chemical composition of silico manganese grade A and B

| Grade A | Grade B |

| %Mn: 65-70 | %Mn: 60-65 |

| %Si:16-18.5 | %Si:14-16 |

| %C: 2 max | %C: 2 max |

| %S:0.05 max | %S: 0.05 max |

| %P: 0.2 max | %P:0.4 max |

Grade A has a higher purity than grade B due to the high weight percentage of silicon and manganese, so the cost of silico manganese price of grade A is higher than B. Therefore, the grade and purity an important factors in determining silicon manganese price and other ferroalloys.

The Impact of quality on silico manganese price

silico manganese prices are intricately linked to its quality and grades. As the demand for high-performance steel continues to rise, manufacturers and steel producers prioritize alloys with specific silicon and manganese content. The scarcity of high-quality silico manganese can drive up its prices, especially when coupled with the intricate production processes involved in refining the alloy.

In contrast, lower-grade silico manganese may find applications in less demanding industries where the emphasis is on cost rather than exceptional steel properties. However, even within lower grades, variations in quality can affect prices as steel producers seek a balance between performance and affordability.

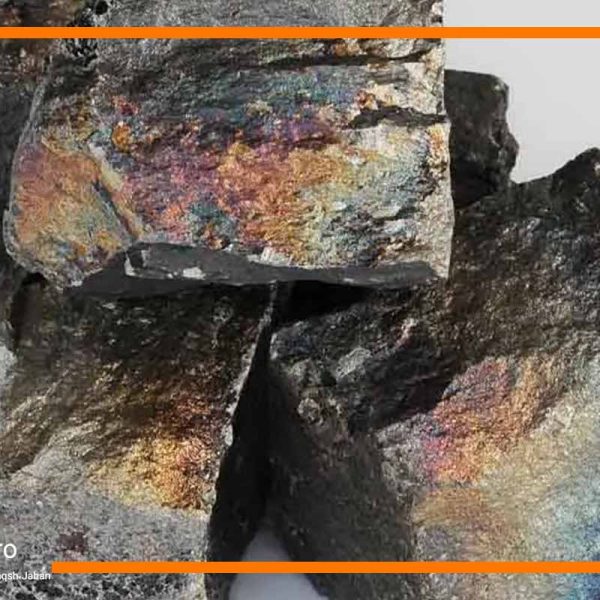

Silico manganese in Pars Manganez Naqsh Jahan

Pars Manganez Naqsh Jahan Company is one of the largest silico-manganese producers in Iran, which is known worldwide for producing high-quality products due to its expert development and research team (R&D), the use of the best raw materials, and the use of modern technologies. In its resume, this company has cooperated with many countries in the world to send silicomanganese. You can contact our experts by email to know the price, get consolation and how to order Silico Manganese. Also, Pars Manganez can customize its products according to your needs.

Conclusion

Silico manganese’s significance in steel production cannot be overstated, and its market dynamics are heavily influenced by the quality and grades of the alloy. As industries increasingly demand high-quality steel with specific attributes, silico manganese prices are likely to continue responding to variations in its composition. Steelmakers and consumers alike must navigate the nuanced landscape of silico manganese to strike a balance between cost and performance in an ever-evolving market.

Reviews

There are no reviews yet.